Having foam on your beer is a good thing, an essential part of a draft beer. But having foam in your draft lines is not only messy, but also forces you to pour perfectly good beer down the drain from head-filled glasses and line purges. What might be a momentary delay on a residential draft line can become a dilemma for a bar, especially on nights where the beer flows fast and requires multiple keg switches.

The Glass Half Empty

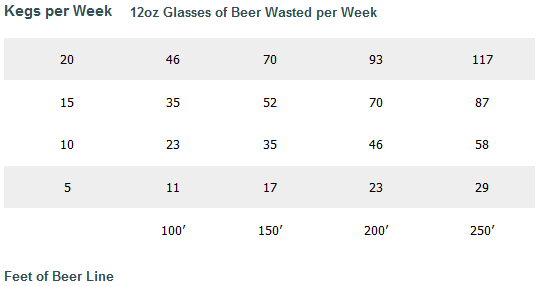

The problem is when a keg is empty of beer, it’s not empty entirely: there’s still foam. Foam will fill up the line, not only causing the beer you’re pouring to suddenly become all head, but also requiring you to purge the line. In the chart below, provided by Micro Matic, you can see how much beer is wasted when a line is filled with foam and has to be purged. The more kegs you have to swap out and the longer your beer lines are, the greater the beer—and profits—you have to pour down the drain.

The Glass Half Full

The solution to this problem is the installation of a FOB or “Foam on Beer” detector between the keg and the line. Beer flows through the FOB, but as soon the beer ends and the foam begins the FOB closes the line before the foam reaches the draft line, leaving your beer uninterrupted and ready for pouring once the new keg is tapped. Since no foam enters the line, you don’t have a glass half-filled with beer and choked the rest of the way with foam. You just swap kegs and keep pouring.

How a FOB Works

Beer runs through the FOB, which contains a compartment with a float. The beer forces the float into the “up” position, allowing beer to flow through the compartment and into the draft line. When the keg empties and foam fills the compartment, the float, no longer held aloft by the beer, drops into the “down” position, cutting off the foam from entering the line. Once a new keg is hooked up the FOB is reset and vented until beer enters the compartment, lifting the float and allowing the beer to enter the line, giving you only continuous beer.

Not all setups will need an FOB. If you’ve got a small bar at home for yourself and a few friends, you might be replacing a single keg each time you invite them over. You’ll also probably using a short line from a keg behind the bar to the taps, not the long lines of commercial bars The longer the line—and the more beer you go through any given day—the more the FOB saves on effort and profits. If you find yourselves wasting more beer due to more keg switches or longer lines, or if you have questions about installing, maintaining, or cleaning FOBs, beer lines, taps and faucets, cooling lines, or gas delivery systems, please contact Clean Beer and our staff will guide you through our services and catalogs.

Leave a Reply